A10V Variable Displacement Piston Pump Instructions

Posted on 19/10/2024

Posted on 19/10/2024

Before installing and using this pump, please read this instruction and other technical information provided by the manufacturer carefully!

1. Precautions

Pump A10V is designed to operate in an open circuit.

System design, installation and commissioning need to be performed by trained technicians and dealers.

Before starting the pump for the first time, it should be filled with clean oil and ensure that the motor rotation direction is consistent with the oil pump rotation direction.

All hydraulic oil ports can only be used to tighten the hydraulic working pipeline. Please respect the tightening torque information provided by our company's samples or manufacturers.

During or shortly after the operation of the pump, the housing and especially the coil may be extremely hot. Please take appropriate safety measures (for example, wear protective clothing).

Note: All data and information provided with the product must be followed.

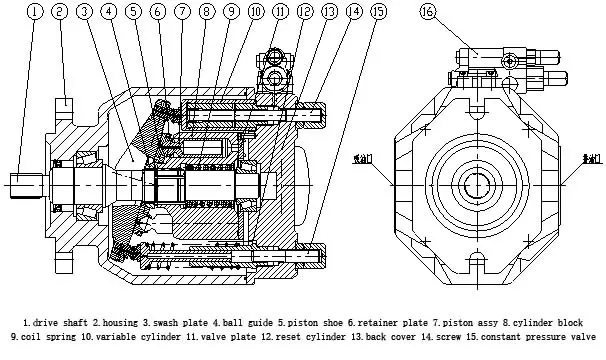

2. Structural diagram

3. Operating conditions

3.1 Hydraulic fluid

Fluid selection:

To ensure trouble-free and efficient operation, the hydraulic fluid for the hydraulic system should be carefully selected during the system design according to the operating conditions. Most mineral oil-based hydraulic fluids are suitable to some extent for axial piston assemblies. Their application depends on water, viscosity and temperature relationship, and takes into account oxidation and corrosion protection, material compatibility, air and water separation characteristics. Operation with refractory fluids is possible with reduced operating data.

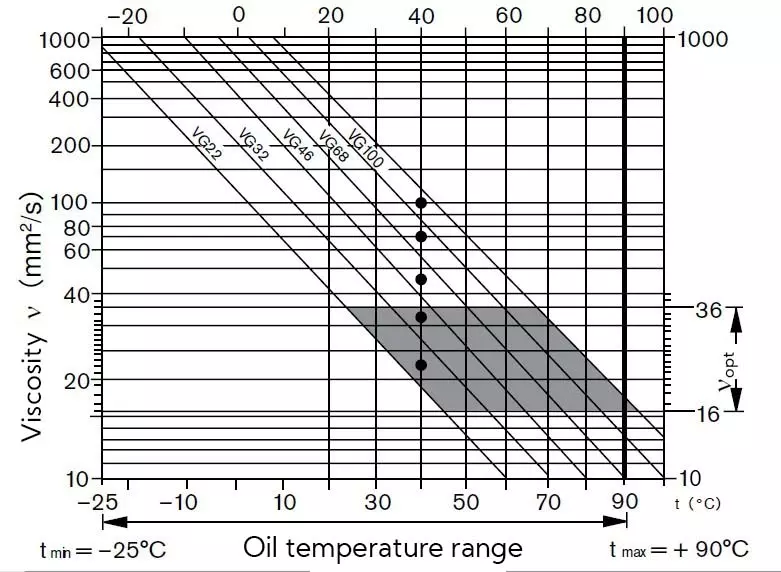

To select the right fluid, it is necessary to know the operating temperature in the tank (open circuit) in relation to the ambient temperature. When selecting a hydraulic fluid, its viscosity should be in the optimal range (νoptimum) within the operating temperature range; see the shaded area in the selection diagram. It is recommended to select a higher viscosity grade in all cases.

Select a chart:

Temperature range (see selection diagram):

tmin = ‐25°C tmax = +90°C

Example: At an ambient temperature of X°C, the operating temperature in the tank is 60°C. Within the optimum viscosity range (νoptimum; shaded area), this temperature corresponds to grade VG 46 or VG 68; selection: VG 68.

Note: The case drain temperature is always higher than the tank temperature, influenced by pressure and velocity. However, the temperature in any part of the system may not exceed 90°C.

Viscosity range

Within the operating viscosity range (between 16 and 100 mm2/s), the device can be operated without technical data restrictions.

For optimum efficiency and service life, it is recommended to select the operating viscosity (at operating temperature) within the following range

νoptimum = Optimum viscosity range 16...36 mm2/s relative to the tank temperature (open circuit).

Viscosity limits

For the operating viscosity in critical operation, see the following values:

νmin = 10 mm2/s

For short periods of time (t < 3 minutes)

At the maximum permissible case drain temperature, tmax = +90 °C.

νmax = 1000 mm2/s

For short periods of time (at cold start, the operating viscosity should be below 100 mm2/s within 15 minutes), tmin = ‐25 °C

Oil filtration The finer the filtration, the cleaner the oil and the longer the life of the axial piston pump.

To ensure reliable operation of the axial piston unit, the cleanliness level should be at least the following:

Level 9 - according to NAS1638; Level 6 - according to SAE; Level 18/15 - according to ISO/DIS4406.

When the oil temperature is very high, the minimum cleanliness is:

Grade 8—according to NAS1638; Grade 5—according to SAE; Grade 17/14—according to ISO/DIS4406.

3.2 Working pressure

Working pressure at the oil inlet

Absolute pressure at port S (inlet): Pabs min 0.8bar; Pabs max 30bar.

Working pressure at the oil outlet

Pressure at port B (outlet): rated pressure Pn 280bar; peak pressure Pmax 350bar.

Oil flow direction

From port S to port B. The reduction in displacement or the increase in speed determines the inlet pressure Pabs at the suction port S (see our company's sample for details). The inlet pressure is the minimum value of the static input pressure or boost pressure.

Case oil drain pressure

The maximum case oil drain pressure (pump body pressure) Pmax is about 4 bar, and this value needs to be reduced under certain working conditions. The allowable case oil drain pressure is related to the pump drive speed (see our company's sample for details).

Tags: Hydraulic Piston Pump, A10V, A10VO, Variable Pump, Displacement, Structural Diagram, Opearting Conditions, Viscosity range