Analysis of Low Volumetric Efficiency of Excavator Steering System

Posted on 05/02/2024

Posted on 05/02/2024

The 60-type wheeled excavator adopts a fully hydraulic deflection front wheel steering system. When making sharp turns while driving, slow front wheel steering often occurs. Most of this kind of failure is caused by the hydraulic steering system's volumetric efficiency and system pressure being too low, and the oil circuit is not smooth. The following is an introduction to the judgment and troubleshooting methods of this fault.

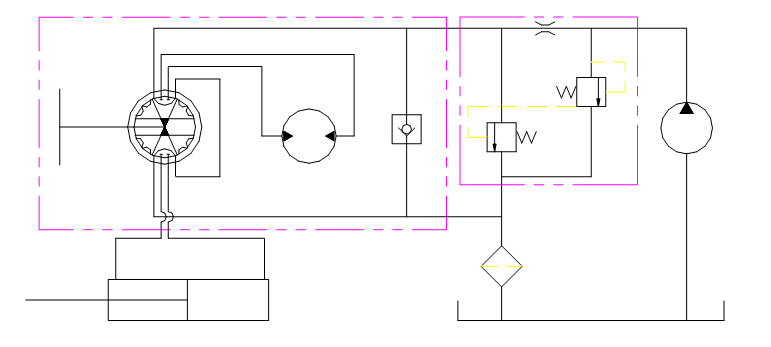

1. How the steering system works

The working principle of the steering system of the 60-type wheeled excavator is shown in the figure. When the engine is running, the steering pump sucks oil from the fuel tank, and the oil it pumps out enters the steering gear through the one-way steady flow valve. When the steering wheel is turned, the spool of the steering valve in the steering gear rotates relative to the valve sleeve, and the pressure oil from the hydraulic pump passes through the steering gear. The valve enters the cycloidal gear motor, passes through the steering valve, and then enters the large cavity of the steering hydraulic cylinder through the central rotary joint to push the wheel to deflect; the oil in the small cavity of the hydraulic cylinder returns to the oil tank through the filter.

If the steering wheel stops rotating, the spool of the steering valve immediately stops rotating. Due to the follow-up action of the valve, the steering valve returns to the intermediate position. The oil path of the steering hydraulic cylinder is blocked, and the oil pumped by the hydraulic pump flows directly back to the tank. The wheels stopped turning.

2. Analysis and troubleshooting of fault causes

According to the working principle of the excavator's hydraulic steering system, when the excavator's front wheels turn slowly during sharp turns, it can be concluded that the volumetric efficiency of the hydraulic steering system and system pressure are too low, and the oil circuit is not smooth. The main reason for the low volumetric efficiency of the hydraulic steering system is serious internal leakage. The following methods can usually be used to check and eliminate it.

1) When the seal between the piston and the cylinder barrel in the steering hydraulic cylinder is worn or damaged, the high-pressure oil in the high-pressure chamber decreases, causing the steering cylinder to move slowly. Inspection method: The steering hydraulic cylinder can be removed and replaced on another excavator with normal steering for testing. If the steering is good after replacement, it means there is no problem with the steering cylinder; if the steering is also slow, it proves that the problem is On the seal of the steering cylinder. At this time, the seal or seal assembly may be replaced as appropriate.

2) When the inner cylindrical surface and sealing ring outside the central rotary joint of the excavator are severely worn, the entire oil and gas system passing through the rotary joint will collude with each other at the seal failure point, causing each system to work insensitively. When turning, its high-pressure oil leaks into the gas line or other hydraulic lines (such as suspension, outriggers), thereby reducing the hydraulic oil supplied to the steering cylinder. Inspection method: Pull up the wheel brake hand-operated air switch. If the gas ejected from it contains oil mist, it means that the central rotary joint is severely worn, causing oil to leak into the gas line. The sealing ring of the central rotary joint needs to be replaced in time. and repair the central swivel joint.

3) When the suction pipe joint of the pump is loose, not tightened, or the oil pipe is broken, air will enter the hydraulic steering system, which will also cause slow steering. Inspection method: Start the engine and observe the fuel tank while turning the steering wheel. As long as bubbles appear in the fuel tank, it means that the suction pipe of the pump is leaking. The pipe joints should be tightened or the damaged suction pipe should be replaced in time.

4) When the working surfaces of the stator and rotor of the steering gear cycloidal gear motor and the working surfaces of the rotary valve are seriously worn, the actual high-pressure oil entering the steering hydraulic cylinder will also be reduced. If the steering cylinder and central rotary joint are in good condition, and the steering wheel is turned to death after the engine is turned off, and the front wheels of the machine can deflect immediately and do not feel heavy, it means there is a problem with the steering gear, and the steering gear should be repaired or replaced immediately.

5) If the internal leakage of the steering hydraulic pump is serious, the mechanical steering will also be slow. An important reason for internal leakage of the steering hydraulic pump is that the gap between the side of the pump's rotor and blades and the end face of the side plate is too large (the normal gap should be within 0.047mm, and the maximum should not exceed 0.1mm). Inspection method: When the performance of the steering hydraulic cylinder, central rotary joint and steering gear is intact, replace it with a new pump for comparison testing. If the steering performance recovers well after replacement, it means that the fault lies in the steering hydraulic pump, and a new pump should be replaced in time.

6) When the steering hydraulic system is too low due to the weakening of the spring force of the single-way steady flow valve, the steering cylinder will also be unable to work and the steering will be slow. At this time, you can remove the nylon plug from the remote control port of the single-way steady flow valve base, install the pressure gauge, start the engine, turn the steering wheel to the left or right, set obstacles on the side of the front wheel, and observe the pressure gauge. reading, if the pressure value does not reach 7MPa, the adjustment screw of the single-way steady flow valve should be tightened appropriately (the fixing nut needs to be loosened first).

7) When the hydraulic oil is not clean or there are foreign objects in the tank, causing the oil circuit of the hydraulic steering system to be blocked or the hydraulic pump to be stuck, it will inevitably cause the machine to turn slowly. For this reason, the hydraulic oil and steering oil tank need to be checked. If they are indeed dirty, the hydraulic oil should be replaced in time and the entire hydraulic steering system should be cleaned.

Tags: Excavator, Piston Pump, Low Volumetric Efficiency, Excavator Steering System