who we are

Get hydraulic spare parts and pumps

you can trust

At Prun Hydraulics services, we believe that all customers or hydraulic equipments these days require specialized services.

Ningbo Prun Hydraulics Co., Ltd is a high-end equipment manufacturer specialized in producing and selling basic hydraulic parts and pumps such as high-pressure piston pumps and motors.

After more than ten years of development, the company has established a unique manufacturing system with a complete set of production processes and equipment for piston pumps and motors. It also has comprehensive international advanced fully automatic processing and hydraulic component testing equipment, and has passed ISO9001 quality system certification.

The company's international trade company (PRUN) is established in Ningbo, with a distribution network covering the whole country and extending globally. The company adheres to the business philosophy of "high quality, fast service, and competitive prices", and strives to enter the top hydraulic component and spare parts manufacturers in China and even the world.

16

years in business

25

+

workshops

10

k+

customers

international sales

About 60% of our products are exported to North America, South America, the Middle East, Southeast Asia, Europe, and Africa. Due to our strict control of product quality and continuous creation of value for our customers, we have successfully increased our sales and production capacity significantly to meet the market demand for our quality products.

Cylinder processing unit

We have two manufacturing plants, a complete set of advanced machines, imported five-axis combined turning and milling machining center, high-precision five-axis vertical machining center, CNC high-speed friction welding machine and other international and domestic advanced processing equipment. At present, it has 9 workshops, 60 CNC machine tools, 30 grinding machines, 8 test benches, etc.

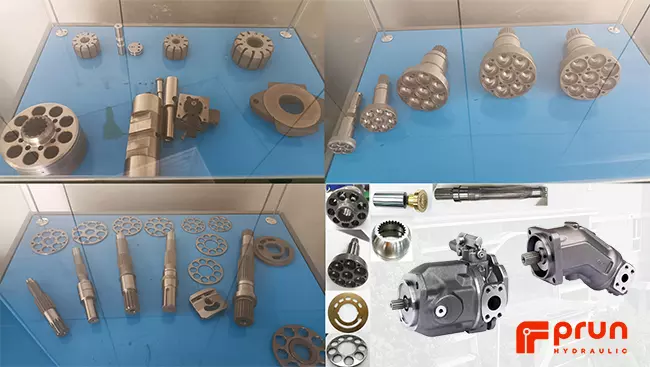

We provide a number of professional production lines for pump body, cylinder block, shaft, disc, plunger and other parts. All core pump parts are produced by ourselves.

PARTS PROCESSING UNIT

The hydraulic pump parts we produce can completely replace original parts, such as Rexroth, Kawasaki, Kobelco, Komatsu, Hitachi, Danfoss, Parker, Toshiba etc. Spare parts include the following:

-

Rotory group

-

Cylinder block

-

Piston shoe

-

Retainer plate

-

Valve plate

-

Drive shaft

-

Swash plate

-

Ball guide

Measurement and Testing Center

Our measurement and testing centers play a key role in ensuring defect-free and high-quality products from materials to finished products.

Incoming material inspection, process inspection, incoming inspection and outgoing inspection ensure our first-class service. Our attentiveness makes our customers' business better.

Products

The company manufactures and supplies a full range of pumps to meet specific customer as well as general market requirements. The products displayed on this website are summarized in the following product ranges:

-

Hydraulic pump parts

-

Hydraulic piston pumps

-

Hydraulic vane pumps

-

Hydraulic valves

-

Hydraulic motors

-

Hydraulic replacement pump parts

-

Hydraulic gear pumps

OUR EXPERTISE

We have solid expertise in:

-

Design and manufacture of hydraulic pumps and parts

-

Machining, Engineering and Precision Casting

-

Design and manufacture of hydraulic motors and parts

-

Hydraulic valve manufacturing

-

Manufacture of other hydraulic parts

Process technology

The products manufactured by our strict process can meet the requirements of different application fields. The process includes the following:

-

Material sawing

-

Material heat treatment

-

Automated processing

-

Heat treatment processing

-

Grinding

-

Super finishing

Rigorous testing

The product to be delivered is 100% tested. We continue to improve the level of testing and aim to achieve zero waste, zero defects and zero failures.

-

1. After the raw materials arrive at our factory, they are inspected (IQC) to check diameter, appearance defects, and material composition.

-

2. Check details before running the production line.

-

3. Full inspection and inspection (IPQC) during mass production.

-

4. Complete cargo inspection (FQC), full inspection of critical dimensions.

-

5. Carry out inspection (QC) after the goods are completed.

-

6.100% pre-shipment inspection and delivery.

Measuring equipments

Prun has very complete testing and measurement facilities. Professional measurement equipment includes three-dimensional coordinate measuring machines, spectrometers, roughness meters, CNC projection measuring machines, cylindrometers, hardness testers, and microscopes etc.

Quality control

Our strong quality management system determines the manufacturing process capability, and we have the system statistical analysis ability to continuously improve the quality of the products produced.

Continuously monitor and manage the stability of the manufacturing process with high-precision machine operation charts. We will continue to invest in research and development. We have a unique technology investment concept, and we have introduced first-class manufacturing equipment from Europe and the United States, providing a reliable guarantee for the production of various high-end products.

ISO 9001:2015 Certified

Our well-established production facilities include professionally designed equipment and machining centers, all operated as per ISO 9001:2015 standards and manufactured in compliance with local and international norms. Prun has been assessed and certified to meet the requirements of ISO 9001:2015.

Inventory

We maintain a large inventory investment in our two factories in Wuxi and our wholly-owned international business center Prun in Ningbo.

Prun supports our global distributors and is able to supply any distributor or customer, providing them with faster and better service.

We supply and support distributors or end customers all over the world, including the United States, Canada, Mexico, Brazil, Argentina, Chile, Colombia, Ecuador, Peru, Uruguay, Australia, Belgium, Italy, United Kingdom, Ukraine, Russia, Saudi Arabia Arabia, Qatar, Syria, Pakistan, Turkey, United Arab Emirates, Iraq, Iran, Vietnam, Malaysia, Thailand, Philippines, Indonesia, Singapore, Tanzania, Egypt, Angola, Algeria, etc.

why us

Benefits of Prun Hydraulics services

Economical Pricing

Economical hydraulic parts and pumps. Get savings up to 15% on hydraulic parts and pumps.

Excellent Quality

Our hydraulic pumps and spare parts are of exceptional quality. Excellent service life in the same industry.

Quick Delivery

We are proud of our fast response time and quick delivery times.

Professional Service

Experienced technical team provide all-round hydraulic technical support to meet every customer demands.

Have Questions? We’re here to help! +86–13355741267

testimonials

What our

customers say

Prun Hydraulics in the world

★★★★★ 5/5

257 Reviews

“Prun has the best pump parts services. I have received high-quality A10VSO parts for repair. Thank you!”

Scott Lisech 22 Nov, 2022

“We're loving it. After using Prun pumps my business skyrocketed! The service was excellent.”

Harrietta 15 Feb, 2023

“I'm looking for China pumps and parts for maintenance, Prun did a great job! The price is quite reasonable.”

Catherine 25 Apr, 2023